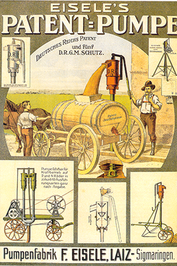

Founding of the company Franz Eisele und Söhne pump factory and iron foundry by the then 23-year-old trained Wagner Franz Eisele at the Laiz location in Sigmaringen.

Company History

In 1903 the introduction of electric motors begins, which Franz Eisele successfully integrates into the product range. His ingenuity is rewarded with the German imperial patent.

Expansion of the company and incorporation of a gray cast iron foundry. A large workshop is built and the company is growing continuously. By 1927 the number of employees rose to around 60.

Company founder Franz Eisele dies at the age of only 62. His sons Josef and Carl Eisele and their brother-in-law Adolf Zeller jointly take over management of the company.

Production is resumed after the war years. During this time the first mobile centrifugal pump was manufactured. Eisele pumps have already become a household name for quality and reliability.

The innovation of the mobile pumps makes it easier to restart.

Start of Drum Trolley production. With the construction of the barrel wagons, the company Franz Eisele und Söhne is once again successfully expanding its product range.

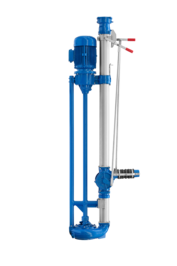

Expansion of the product portfolio with upright vertical pumps with an electric motor, PTO drive or a combination of both, as well as the first mobile submersible motor pump with forced cooling.

In 1980 Bernd Eisele took over the management, and from 1985 he was supported by his brother Michael Eisele. As a result, the product portfolio for agriculture will be continuously developed.

The innovative new and further developments from 1982-1985 include the submersible motor agitators, submersible motor pumps and the first rotary lobe pump from Eisele. The quality and reliability of the devices underline the company's reputation:

Made in Germany.

Continuous development and expansion of production using the latest production standards as well as technical innovation and taking into account the constantly changing conditions.

Eisele pumps and agitators are now known all over the world and are in constant use!

Due to the concentration on the core business, the barrel wagon construction is discontinued.

A new production hall is being built and, with a view to the digital future, numerous operational processes are being optimized for their efficiency with the help of process-oriented solutions.

The new production hall is opened and the test center completed, which will be used for research and development purposes in the future. All pumps and agitators can be checked for their performance here.

Dominik Eisele joins the family business in the fifth generation.

In order to create the basis for further growth in European and international markets, he introduces many innovations and digitization measures.

These lead to more efficient processes, from which the more than 100 employees also benefit due to greater transparency.

The further development of the company continues:

In 2018, the new, ultra-modern and energy-efficient paint shop will go into operation. Contract manufacturing via the plate boring mill is reduced and production is optimized with regard to the core business.

As part of a comprehensive brand relaunch, the company's color and visual language has been fundamentally revised.

On the new website, this also serves to ensure consistent user guidance.

The modernized company logo symbolizes movement and shows that time does not stand still at Eisele. The new company slogan "Knowledge in motion" also underlines the focus on more agility.

The construction of a new administration building is on the plan in 2022.