EISELE expands IE5 product portfolio, highlights new grant opportunities |

| Grant rules have changed again – now the range of units eligible for grants is larger than ever before |

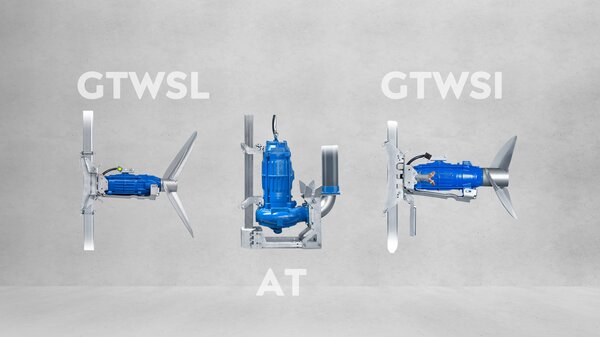

| Sigmaringen (Germany), 23 May 2024. Eisele, a leading manufacturer of pumps and agitators for the agricultural and biogas sectors, has made significant additions to its range of products featuring IE5 technology. As of now, certain power classes of AT submersible motor pumps (11 kW, 15 kW, 18.5 kW) as well as GTWSB-E submersible mixers and GTWSL-E large-propeller submersible mixers are also equipped with this subsidisable technology. Considerable energy cost savings can be realised as a result. AT pumps and the GTWSB units are available with an ATEX certificate. Alongside BAFA grants, the German Federal Office for Agriculture and Food (BLE) offers subsidies of up to 30% for primary production farms in its current funding programme. Simple calculation for smart savings An updated grant information flyer demonstrates how exploding electricity prices can be brought under control with energy efficiency class IE5 and the associated subsidies: In a tank with diameter 28 m and a depth of 6 m, two Eisele submersible mixers of type GTWSB 206-E can achieve annual electricity cost savings of over EUR 14,000 compared to conventional mixers available on the market. The mixers and pumps have motors that meet energy efficiency class IE5 and reach an efficiency of up to 96%, which can contribute to electricity savings of up to 45%. New grant rules in Germany Further cost savings are possible by taking advantage of new grant incentives. The rules underwent a significant revision at the end of February this year. As a result, a replacement investment can be even more worthwhile, especially for small companies. In Germany, the Federal Office of Economics and Export Control (BAFA) offers an investment subsidy of up to 25% under module 1 of its support programme. Under module 4, energy optimisation measures are also eligible for a subsidy, of up to 15%. Support is available to all electricity-generating undertakings under the so-called General Block Exemption Regulation (GBER). On top of this, there is the BLE programme offering grants of up to 30%. All in all, this opens up completely new grant opportunities. Eisele takes care of the application Another point to note with IE5 motor technology is that prospective buyers do not need an energy advisor when applying for a module 1 grant and basic funding under module 4. An energy-saving concept is not required, and the application process is simple. Eisele can take care of the application, which avoids any extra costs. For all pumps and mixers with IE5 synchronous motors, Eisele supplies the appropriate frequency converter ready set up. This is also fully eligible for BAFA and BLE grants. Markus Blender, Key Account Manager at Eisele, says: “Eisele is committed to sustainability. We achieve an efficiency of up to 96% with our IE5 energy-saving motors. This means that we offer the highest energy-saving potential currently possible on the market. The IE5 energy efficiency class for submersible mixers and pumps with and without ATEX approval is unique in the world at this time.” Example: most economical mixer in the world Eisele’s GTWSL-E large-propeller submersible mixers enable a high circulation rate with low drive power. The IE5 energy-saving motor, large propeller diameters, slow speeds and low drive power make the GTWSL-E the most economical mixer in the world to date. Its synchronous drive motor – optionally 11 kW or 15 kW – achieves impressive circulation performance with enormous thrust. The frequency converter enables stepless speed control for optimal adaptation to different operating conditions. The weight and solid design of the unit enable low-vibration running characteristics, even with high dry matter content, while ensuring effective heat dissipation. GTWSL-E mixers can be used in biogas plants at immersion depths of up to 40 m. They are approved for substrate temperatures up to 65 °C, making them suitable for thermophilic plant operation. |